Identification of design margins in the design of a strut

Defining the components of the margin analysis network

The components of the margin analysis network are:

Input parameters

Design parameters

Fixed parameters

Input specifications

Intermediate parameters

Decision nodes

Output parameters

Performance parameters

Target thresholds

Decided values

Design parameters

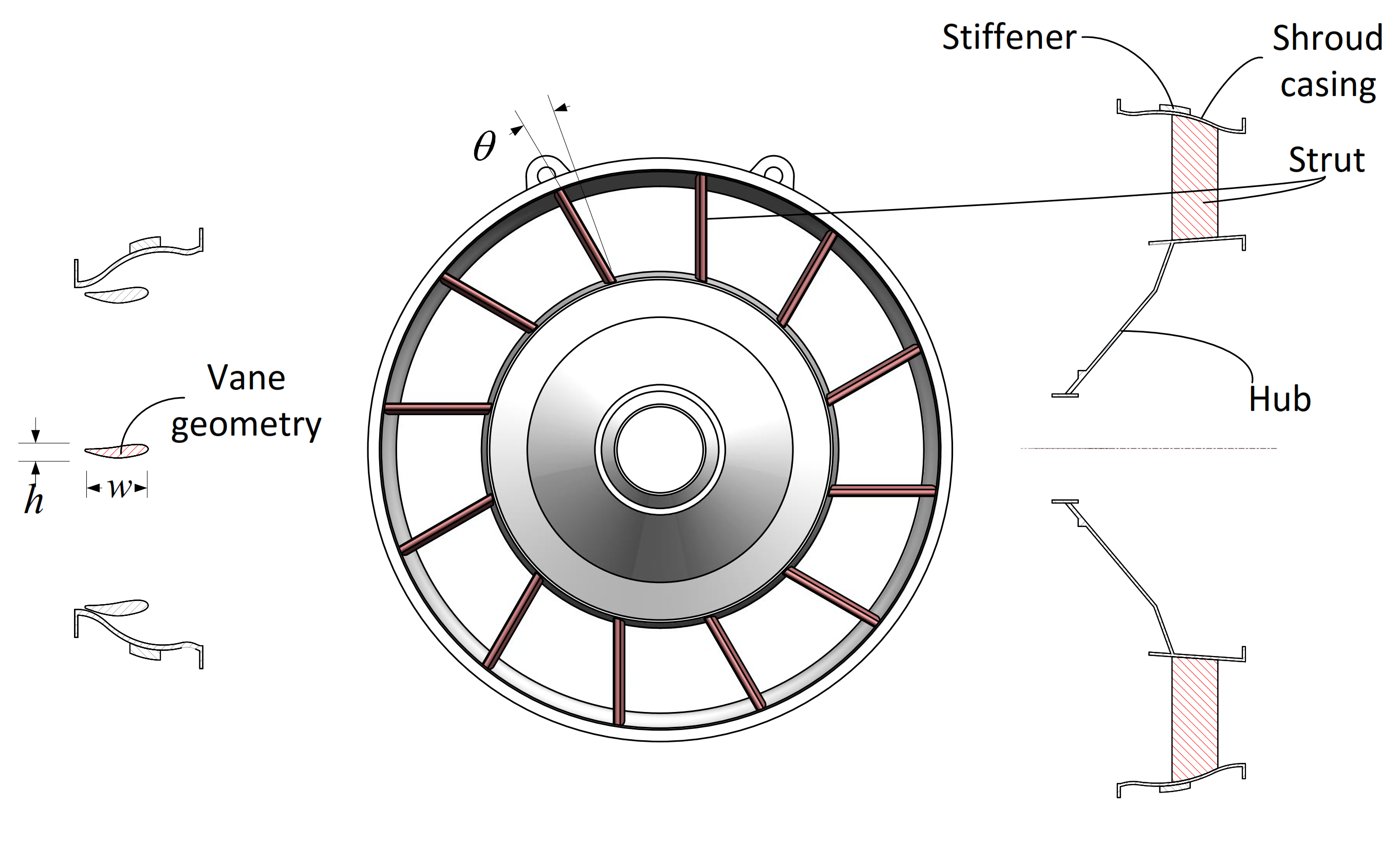

Fig.1 Schematic of strut design example

This example shows how to evaluate the design margins of a strut which is a part of the turbine rear frame of an aeroengine. In this example, we consider three design parameters of the strut the lean angle \(\theta\), the vane width \(w\), and the vane height \(h\)

[1]:

from mvm import DesignParam

# define design parameters

d1 = DesignParam(100.0, 'D1', universe=(70.0, 130.0), variable_type='FLOAT', description='vane length', symbol='w')

d2 = DesignParam(15.0, 'D2', universe=(5.0, 20.0), variable_type='FLOAT', description='vane height', symbol='h')

d3 = DesignParam(10.0, 'D3', universe=(0.0, 30.0), variable_type='FLOAT', description='lean angle', symbol='theta')

design_params = [d1,d2,d3]

Fixed parameters

We also specify some constants for this example, such as elastic modulus \(E\), coefficient of thermal expansion \(\alpha\), hub and shroud radii, \(r_1\) and \(r_2\), respectively, and ambient temperature \(T_\mathrm{sink}\)

[2]:

from mvm import FixedParam

# define fixed parameters

i1 = FixedParam(7.17E-06, 'I1', description='Coefficient of thermal expansion', symbol='alpha')

i2 = FixedParam(156.3E3, 'I2', description='Youngs modulus', symbol='E')

i3 = FixedParam(346.5, 'I3', description='Radius of the hub', symbol='r1')

i4 = FixedParam(536.5, 'I4', description='Radius of the shroud', symbol='r2')

i5 = FixedParam(25.0, 'I6', description='ambient temperature', symbol='T_sink')

fixed_params = [i1, i2, i3, i4, i5]

Input specifications

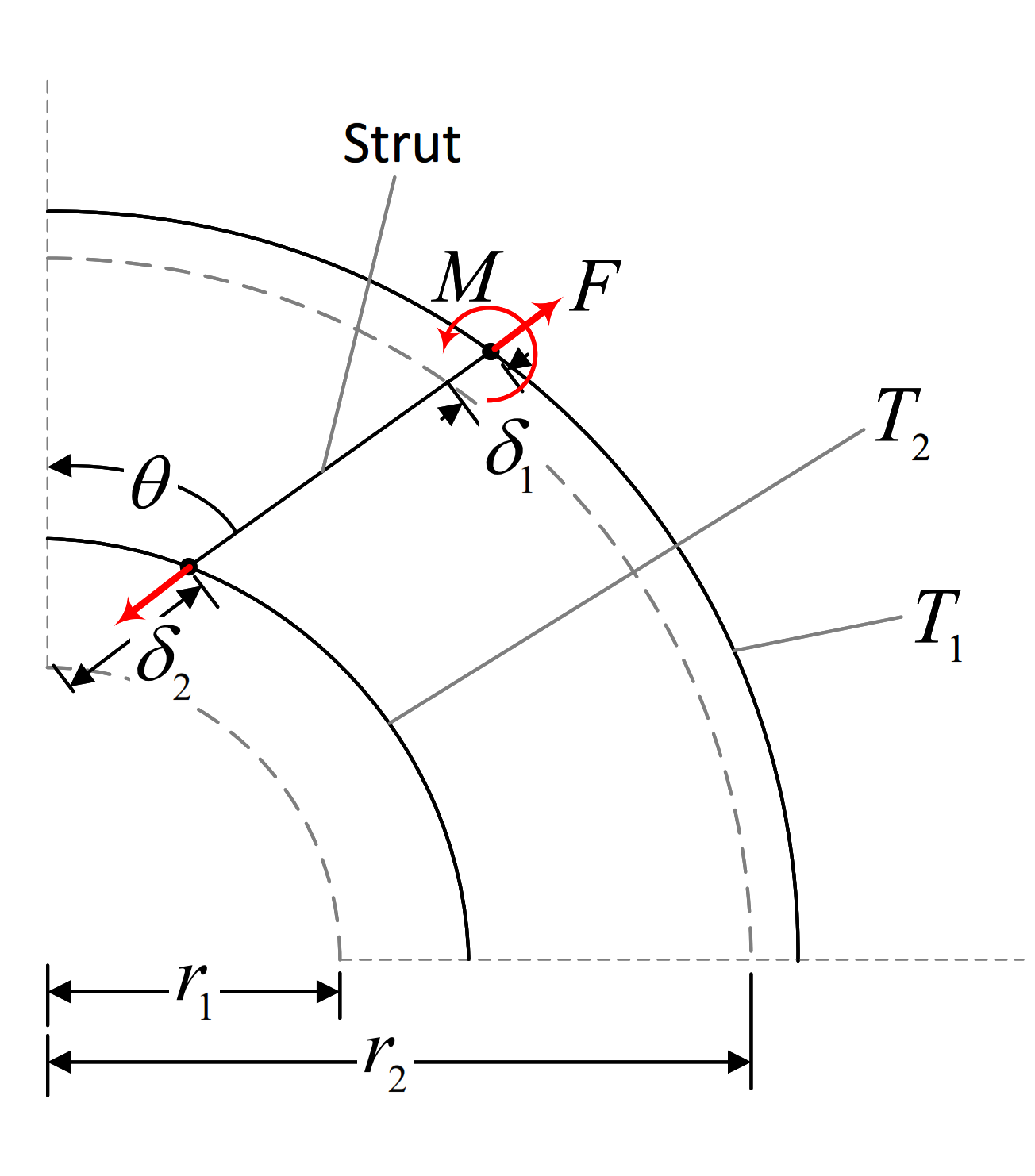

The strut experiences a compressive force \(F\) and bending moment \(M\) as a result of non-uniform expansion of the turbine rear frame during operation. This is attributed to two temperatures \(T_1\) and \(T_2\) that occur at the shroud and hub surfaces, respectively as shown below:

Fig.2 Temperature loads

The temperatures \(T_1\) and \(T_2\) are defined as input specifications. The argument inc specifies the expected direction of change of these temperatures during operation and will be used later on to compute the ability of a design margin to absorb change of said temperatures

\(T_1\) is expected to decrease by 1% of the nominal value

\(T_2\) is expected to increase by 1% of the nominal value

If the absolute change is to be specified, then change the argument inc_type to 'abs'

[3]:

from mvm import InputSpec

# define input specifications

s1 = InputSpec(450, 'S1', universe=[325, 550], variable_type='FLOAT', description='nacelle temperature',

symbol='T1', inc=-1e-0, inc_type='rel')

s2 = InputSpec(425, 'S2', universe=[325, 550], variable_type='FLOAT', description='gas surface temperature',

symbol='T2', inc=+1e-0, inc_type='rel')

input_specs = [s1, s2]

Performance parameters

we then calculate weight and cost as:

where \(c\) is the raw material cost per unit weight. and \(L\) is the length of the strut given by \(L = -r_1\cos{\theta} + \sqrt{{r_2}^2 - {r_1}^2\sin^2{\theta}}\)

\(W\) and \(\mathrm{cost}\) are performance parameters. Their calculation is given by a behaviour model b1

[4]:

from mvm import Behaviour

import numpy as np

# this is the weight and cost model

class B1(Behaviour):

def __call__(self, rho, w, h, theta, r1, r2, cost_coeff):

L = -r1 * np.cos(np.deg2rad(theta)) + np.sqrt(r2 ** 2 - (r1 * np.sin(np.deg2rad(theta))) ** 2)

weight = rho * w * h * L

cost = weight * cost_coeff

self.performance = [weight, cost]

b1 = B1(n_i=0, n_p=2, n_dv=0, n_tt=0, key='B1')

We specify whether increasing this parameter is beneficial or detrimental to the design’s performance using the direction argument

[5]:

from mvm import Performance

# Define performances

p1 = Performance('P1', direction='less_is_better')

p2 = Performance('P2', direction='less_is_better')

performances = [p1, p2]

Target thresholds

The strut must support the forces shown perviously on Figure 2:

A compressive stress \(\sigma_a\) due to the force \(F\)

A bending stress \(\sigma_m\) due to the bending moment \(M\)

The maximum stress value becomes the target threshold.

This is defined by behaviour model b2

[6]:

# this is the stress model

class B2(Behaviour):

def __call__(self, T1, T2, h, theta, alpha, E, r1, r2, T_sink):

L = -r1 * np.cos(np.deg2rad(theta)) + np.sqrt(r2 ** 2 - (r1 * np.sin(np.deg2rad(theta))) ** 2)

sigma_a = (E * alpha) * ((T2 * r2) - (T1 * r1) - (T_sink * (r2 - r1))) * np.cos(np.deg2rad(theta)) / L

sigma_m = (3 / 2) * ((E * h) / (L ** 2)) * (

alpha * ((T2 * r2) - (T1 * r1) - (T_sink * (r2 - r1))) * np.sin(np.deg2rad(theta)))

self.threshold = max([sigma_a, sigma_m])

b2 = B2(n_i=0, n_p=0, n_dv=0, n_tt=1, key='B2')

Decided values (from Decision nodes)

After calculating the target thresholds (what the design needs to do) we have to make decisions regarding certain ‘off-the-shelf’ components. The decided value in this case is given by the yield stress of the selected material. We define a decision node using the Design class and a corresponding Behaviour model to translate the selected material to a decided value. The material model also supplies two additional intermediate parameters that are required by the cost model in b1. They

are the density \(\rho\) and the cost density \(c\)

[7]:

from mvm import Decision

class B3(Behaviour):

def __call__(self, material):

material_dict = {

'dummy' : {

'sigma_y' : 92, # MPa

'rho' : 11.95e-06, # kg/mm3

'cost' : 0.1 # USD/kg

},

'Steel' : {

'sigma_y' : 250, # MPa

'rho' : 10.34e-06, # kg/mm3

'cost' : 0.09478261, # USD/kg

},

'Inconel' : {

'sigma_y' : 460, # MPa

'rho' : 8.19e-06, # kg/mm3

'cost' : 0.46, # USD/kg

},

'Titanium' : {

'sigma_y' : 828, # MPa

'rho' : 4.43e-06, # kg/mm3

'cost' : 1.10 # USD/kg

},

}

chosen_mat = material_dict[material]

self.intermediate = [chosen_mat['rho'], chosen_mat['cost']]

self.decided_value = chosen_mat['sigma_y']

return self.decided_value

b3 = B3(n_i=2, n_p=0, n_dv=1, n_tt=0, key='B3')

# Define decision nodes and a model to convert to decided values

decision_1 = Decision(universe=['Steel', 'Inconel', 'Titanium'], variable_type='ENUM', key='decision_1',

direction='must_not_exceed', decided_value_model=b3, description='The type of material')

decisions = [decision_1, ]

We concatenate all behaviour models into a list

[8]:

behaviours = [b1,b2,b3]

Excess margins

The design must support the following loads

A maximum stress less than the yield stress \(\sigma_y\)

We have one design margin given by:

It is of the must_not_exceed type

[9]:

from mvm import MarginNode

# Define margin nodes

e1 = MarginNode('E1', direction='must_not_exceed')

margin_nodes = [e1,]

Calculation of the value of excess margins in the strut

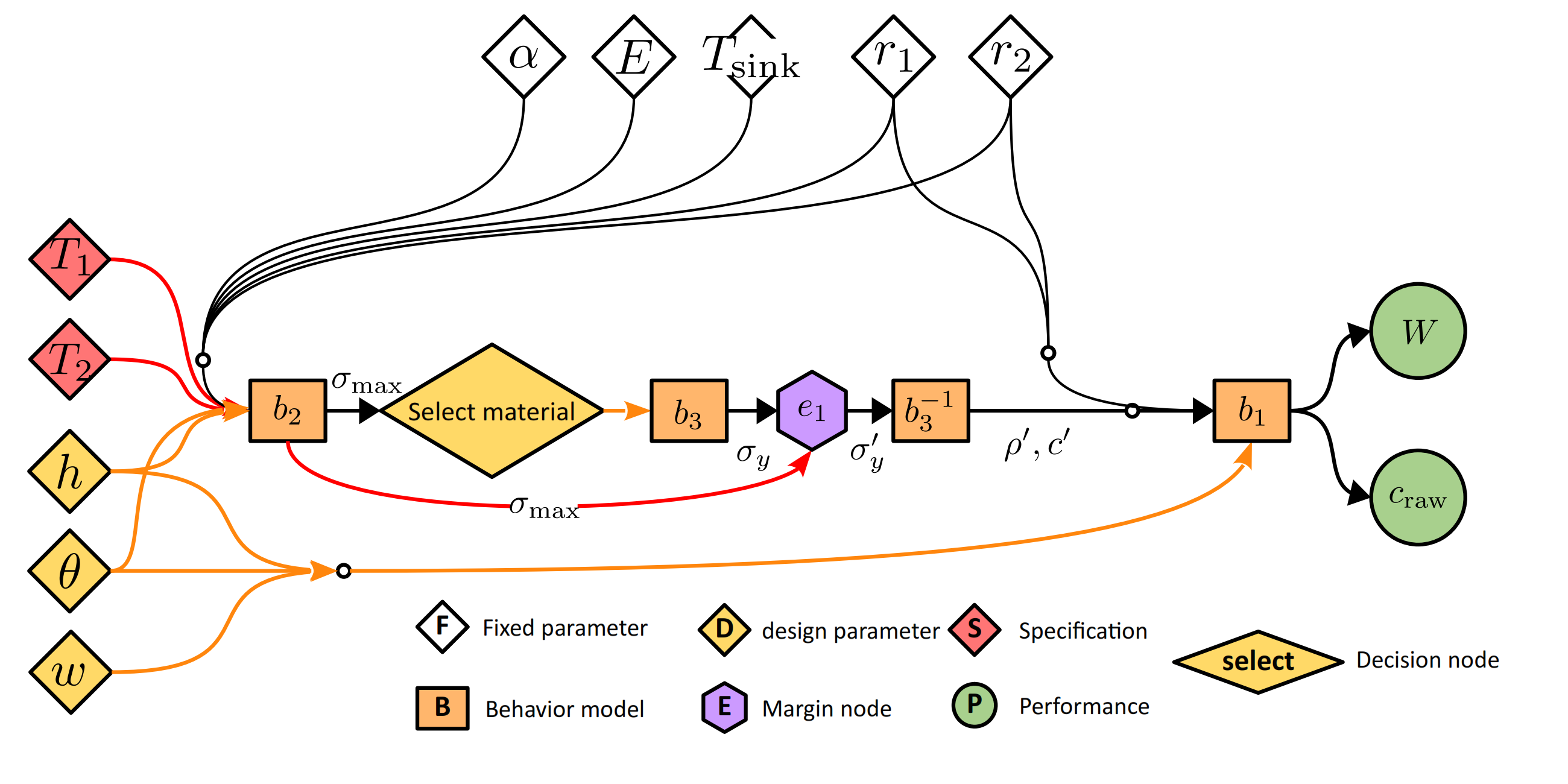

Constructing the margin analysis network

We combine all the perviously defined parameters and behaviour models inside a MarginNetwork object. The forward method represents a single calculation pass of the margin analysis network

The randomize method is optional and is used to randomly seed any probabilistic input specifications or behaviour models (see example in next section). The MAN object below mimics the MAN shown in the figure below:

Fig.3 Margin analysis network of the strut example

[10]:

from mvm import MarginNetwork

# Define the MAN

class MAN(MarginNetwork):

def randomize(self):

pass

def forward(self, num_threads=1, recalculate_decisions=False, allocate_margin=False, strategy=['min_excess',], outputs=['dv',]):

# retrieve MAN components

w = self.design_params[0].value # w

h = self.design_params[1].value # h

theta = self.design_params[2].value # theta

T1 = self.input_specs[0].value # T1 (could be stochastic)

T2 = self.input_specs[1].value # T2 (could be stochastic)

alpha = self.fixed_params[0].value # alpha

E = self.fixed_params[1].value # E

r1 = self.fixed_params[2].value # r1

r2 = self.fixed_params[3].value # r2

T_sink = self.fixed_params[4].value # T_sink

b1 = self.behaviours[0] # calculates weight and cost

b2 = self.behaviours[1] # calculates maximum of axial and bending stresses

b3 = self.behaviours[2] # calculates material properties

decision_1 = self.decisions[0] # select a material based on maximum bending or axial stress

e1 = self.margin_nodes[0] # margin against axial or bending failure (sigma_max,sigma_y)

p1 = self.performances[0] # weight

p2 = self.performances[1] # cost

# Execute behaviour models

# T1, T2, h, theta, alpha, E, r1, r2, T_sink

b2(T1, T2, h, theta, alpha, E, r1, r2, T_sink)

sigma_max = b2.threshold # the applied load as the target threshold

# Execute decision node and translation model

decision_1(sigma_max, recalculate_decisions, allocate_margin, strategy[0], num_threads, outputs[0])

sigma_prime = decision_1.output_value # this either the target threshold (sigma_max) or the decided value (sigma_y)

sigma_y = decision_1.decided_value # the yield stress of the chosen material

# invert decided value: to get rho, and cost_coeff

b3.inv_call(sigma_prime)

rho = b3.intermediate[0]

cost_coeff = b3.intermediate[1]

# Compute excesses

e1(sigma_max, sigma_y)

# Compute performances

# rho, w, h, theta, r1, r2, cost_coeff

b1(rho, w, h, theta, r1, r2, cost_coeff)

p1(b1.performance[0])

p2(b1.performance[1])

man = MAN(design_params, input_specs, fixed_params,

behaviours, decisions, margin_nodes, performances, 'MAN_1')

Calculating the impact of excess margin on performance

To calculate the level of overdesign w.r.t margin node \(m\) and performance parameter \(j\) given by

we need to calculate the threshold performance \(p^\text{threshold}_{mj}\), i.e., the weight of a hypothetical design where margin node \(e_m = 0\), To do so, we construct a surrogate model associated with each behaviour model that is connected to a decision node to allow interpolation of this hypothetical design. In this example it is b3 associated with decision_1.

This allows the MAN’s performance parameters \(\mathbf{p}\) to be expressed as functions in terms of the margin values \(\mathbf{e}\) and input specifications \(\mathbf{s}\)

we substitute \(e_m = 0\) while holding all the other components at their nominal values.

[11]:

# train material surrogate

variable_dict = {

'material' : {'type' : 'ENUM', 'limits' : decision_1.universe},

}

b3.train_surrogate(variable_dict,n_samples=50,sm_type='KRG')

b3.train_inverse(sm_type='LS')

___________________________________________________________________________

LS

___________________________________________________________________________

Problem size

# training points. : 50

___________________________________________________________________________

Training

Training ...

Training - done. Time (sec): 0.0009418

/home/khalil/.local/share/virtualenvs/mvmlib-9r_YoSyI/lib/python3.10/site-packages/smt/surrogate_models/krg_based.py:211: UserWarning: Warning: multiple x input features have the same value (at least same row twice).

warnings.warn("Warning: multiple x input features have the same value (at least same row twice).")

We now calculate the impact using mvmlib using the Kriging surrogate model

[12]:

man.reset()

man.init_decisions()

man.allocate_margins()

man.forward()

man.compute_impact()

man.impact_matrix.value

[12]:

array([[-0.08317867, 0.26427108]])

The margin node (against yielding) has a positive impact on cost (i.e., its elimination will increase raw material cost).

However, the margin node (against yielding) has a negative on weight (i.e., its elimination will reduce weight).

Calculation of change absorption capability

We now calculate the ability of the design to absorb deviation in the input specifications from their nominal values. We incrementally increase or decrease each specification \(s_i\) until one of the margin nodes is equal to 0. The value of the specification at this point is called \(s^\text{max}_i\). The maximum allowable deterioration in the input specification is give by

[13]:

man.compute_absorption()

man.spec_vector - man.deterioration_vector.value * man.spec_vector

[13]:

array([414. , 403.75])

The value of the target thresholds when \(s^\text{max}_i\) is reached is \(\mathbf{t}^\text{new}\). The value of the target thresholds at the nominal specifications \(s_i\) is \(\mathbf{t}^\text{nominal}\). The change absorption per unit deterioration is given by

[14]:

man.absorption_matrix.value

[14]:

array([[2.31557453, 3.38611472]])

Aggregation of impact and absorption

We average the absorption and impact across all input specifications and performance parameters for each margin node (assuming equal weighting)

as follows:

[15]:

mean_absorption_node_1 = np.mean(man.absorption_matrix.value,axis=1)[0]

mean_impact_node_1 = np.mean(man.impact_matrix.value,axis=1)[0]

print(mean_absorption_node_1,mean_impact_node_1)

2.850844625951363 0.09054620735655292

Alternatively, we can aggregate across margin nodes instead

as follows:

[16]:

mean_absorption_spec_1 = np.mean(man.absorption_matrix.value,axis=0)[0]

mean_absorption_spec_2 = np.mean(man.absorption_matrix.value,axis=0)[1]

mean_impact_perf_1 = np.mean(man.impact_matrix.value,axis=0)[0]

mean_impact_perf_2 = np.mean(man.impact_matrix.value,axis=0)[1]

print(mean_absorption_spec_1,mean_impact_perf_1)

print(mean_absorption_spec_2,mean_impact_perf_2)

2.3155745312790024 -0.0831786667397811

3.3861147206237234 0.2642710814528869

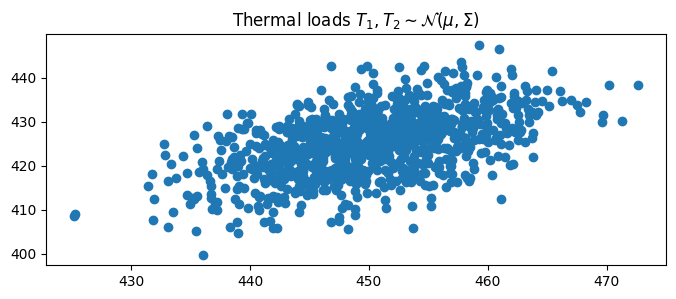

Effect of uncertainty in the nominal values of the input specifications \(T_1\) and \(T_2\)

This caused by unequal temperatures \(T_1\), and \(T_2\). Their exact values are not known and are expected to vary. We model this uncertainty using a joint probability density function:

where \(\boldsymbol{\mu}\) and \(\boldsymbol{\Sigma}\) are the means and covariances, respectively of multivariate normal distribution. For more examples of different probability density functions supported by the library, see the examples here

[17]:

from mvm import GaussianFunc, UniformFunc

import numpy as np

# T1,T2 distribution (Gaussian)

center = np.array([450, 425])

Sigma = np.array([

[50, 12.5],

[37.5, 50],

])

Requirement = GaussianFunc(center, Sigma, 'temp')

Requirement.random(1000)

Requirement.view(xlabel='Thermal loads $T_1,T_2 \

\sim \mathcal{N}(\mu,\Sigma)$')

Requirement.reset()

We define the random input specifications as follows by supplying the arguments cov_index and distribution

[18]:

from mvm import InputSpec

# define input specifications

s1 = InputSpec(center[0], 'S1', universe=[325, 550], variable_type='FLOAT', cov_index=0,

description='nacelle temperature', distribution=Requirement,

symbol='T1', inc=-1e-0, inc_type='rel')

s2 = InputSpec(center[1], 'S2', universe=[325, 550], variable_type='FLOAT', cov_index=1,

description='gas surface temperature', distribution=Requirement,

symbol='T2', inc=+1e-0, inc_type='rel')

input_specs = [s1, s2]

Instead of redifining the MAN from scratch, we can subclass the original deterministic MAN and extend it by defining the randomize method to allow the MAN to draw random samples on input specs \(T_1\) and \(T_2\). The new stochastic version of the previous MAN is defined by StoMAN

[19]:

# Define the stochastic MAN

class StoMAN(MAN):

def randomize(self):

s1 = self.input_specs[0]

s2 = self.input_specs[1]

s1.random()

s2.random()

sto_man = StoMAN(design_params,input_specs,fixed_params,

behaviours,decisions,margin_nodes,performances,'MAN_2')

We use a Monte-Carlo simulation to obtain the distribution of impact and absorption in the design

[20]:

import sys

# Perform Monte-Carlo simulation

n_epochs = 1000

for n in range(n_epochs):

sys.stdout.write("Progress: %d%% \r" %((n/n_epochs)* 100)) # display progress

sys.stdout.flush()

sto_man.randomize()

sto_man.init_decisions()

sto_man.allocate_margins()

sto_man.forward()

sto_man.compute_impact()

sto_man.compute_absorption()

Progress: 12%

Progress: 99%

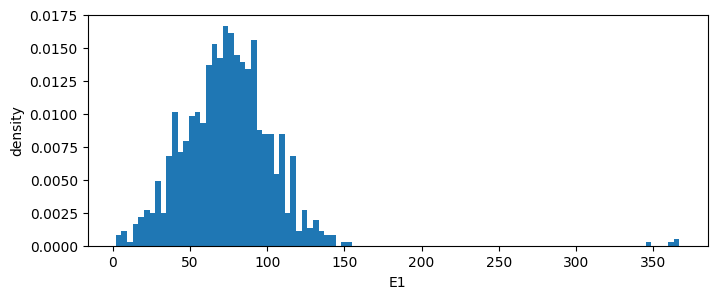

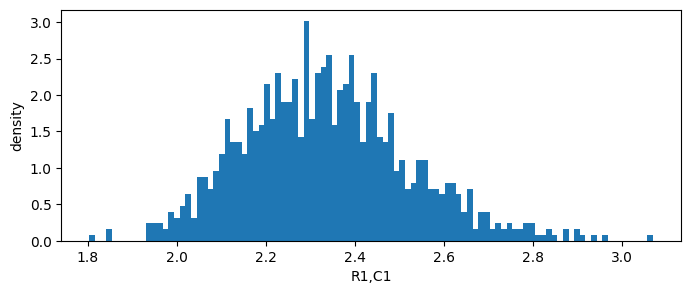

We view the distribution of excess

[21]:

# View distribution of excess

sto_man.margin_nodes[0].excess.view()

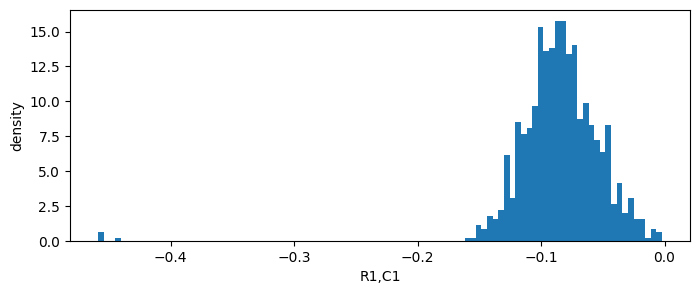

we view the distribution of impact on performance

[22]:

# View distribution of Impact on Performance

sto_man.impact_matrix.view(0,0)

sto_man.impact_matrix.view(0,1)

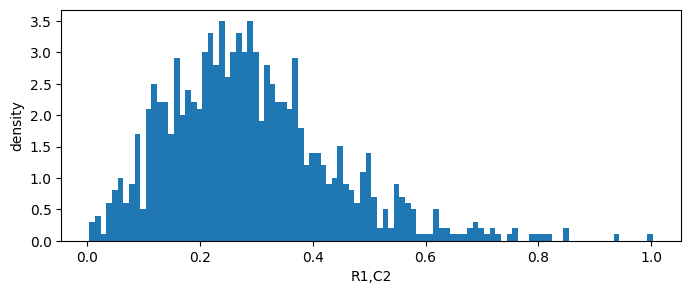

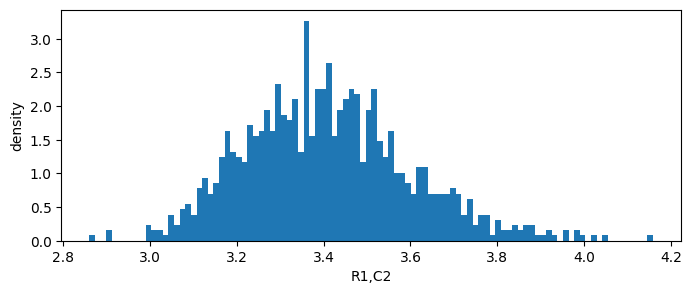

We view the distribution of change absorption capability of margin node 1

[23]:

sto_man.absorption_matrix.view(0,0)

sto_man.absorption_matrix.view(0,1)

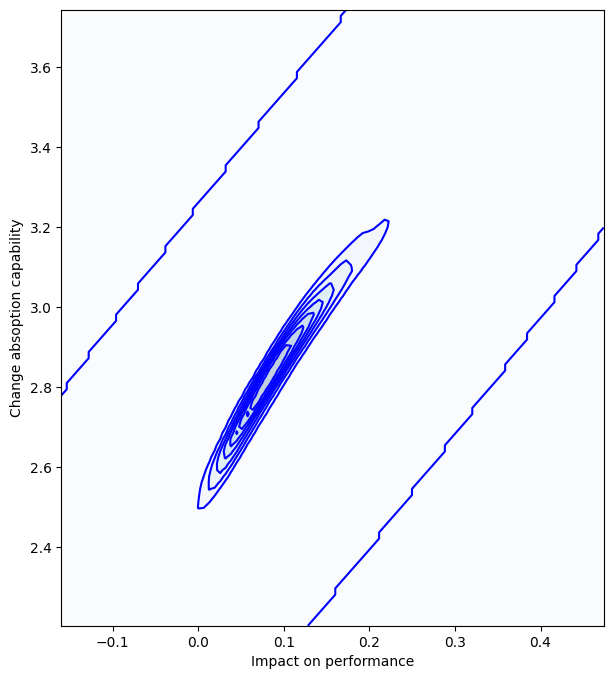

Finally, we view the margin value plot

[24]:

# display the margin value plot

sto_man.compute_mvp('scatter')

sto_man.compute_mvp('density')

[24]:

0.011306362998459859

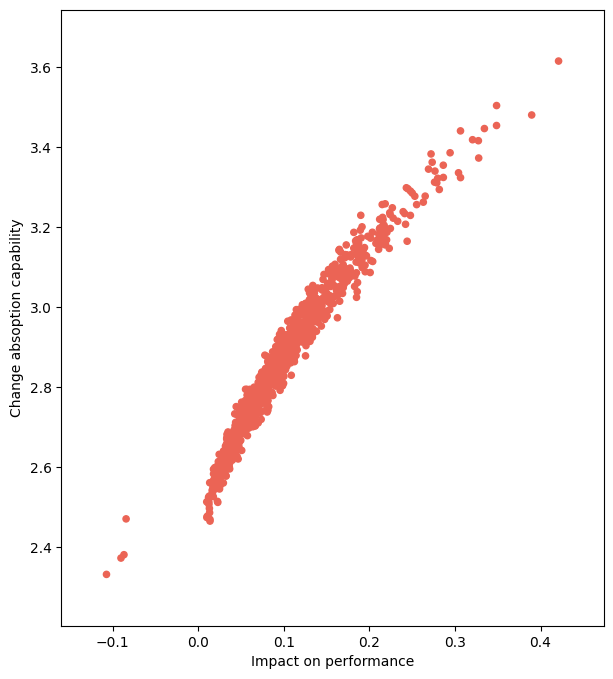

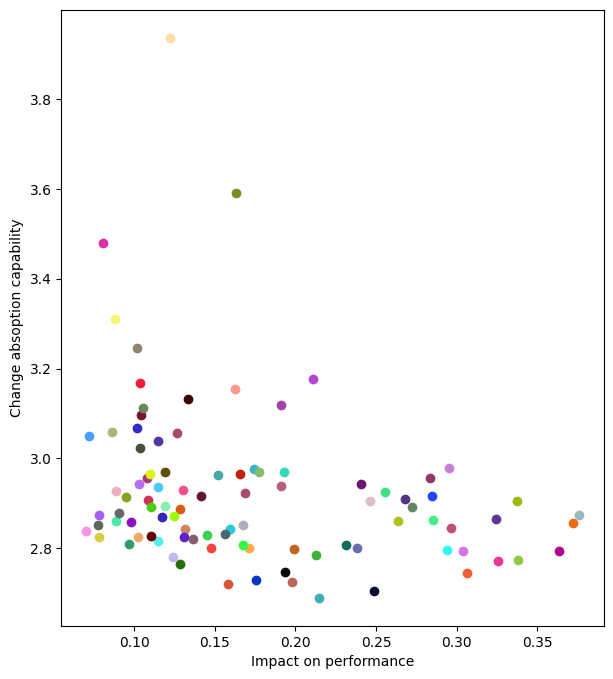

The effect of design parameters on change absorption and impact on performance

Let us look at an alternative design given by different values of \(w\), \(h\), and \(\theta\)

[25]:

from mvm import Design

import matplotlib.pyplot as plt

# Effect of alternative designs

n_designs = 100

n_epochs = 10

lb = np.array(man.universe_d)[:, 0]

ub = np.array(man.universe_d)[:, 1]

design_doe = Design(lb, ub, n_designs, 'LHS')

# create empty figure

fig, ax = plt.subplots(figsize=(7, 8))

ax.set_xlabel('Impact on performance')

ax.set_ylabel('Change absoption capability')

X = np.empty((1,len(man.margin_nodes)))

Y = np.empty((1,len(man.margin_nodes)))

D = np.empty((1,len(man.design_params)))

for d,design in enumerate(design_doe.unscale()):

sto_man.nominal_design_vector = design

sto_man.reset()

sto_man.reset_outputs()

# Perform Monte-Carlo simulation

for n in range(n_epochs):

sys.stdout.write("Progress: %d%% \r" % ((d * n_epochs + n) / (n_designs * n_epochs) * 100))

sys.stdout.flush()

sto_man.randomize()

sto_man.init_decisions()

sto_man.allocate_margins()

sto_man.forward()

sto_man.compute_impact()

sto_man.compute_absorption()

# Extract x and y

x = np.mean(sto_man.impact_matrix.values,axis=(1,2)).ravel() # average along performance parameters (assumes equal weighting)

y = np.mean(sto_man.absorption_matrix.values,axis=(1,2)).ravel() # average along input specs (assumes equal weighting)

if not all(np.isnan(y)):

X = np.vstack((X,x))

Y = np.vstack((Y,y))

D = np.vstack((D,design))

# plot the results

color = np.random.random((1,3))

ax.scatter(x,y,c=color)

plt.show()

Progress: 99%

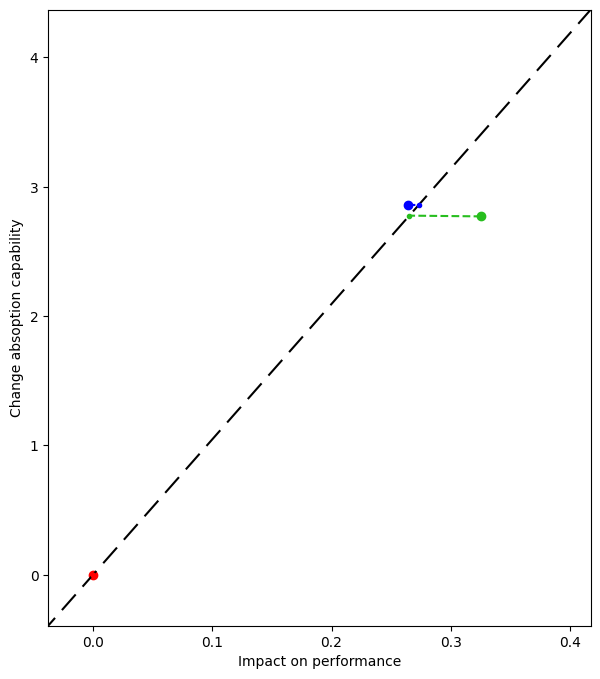

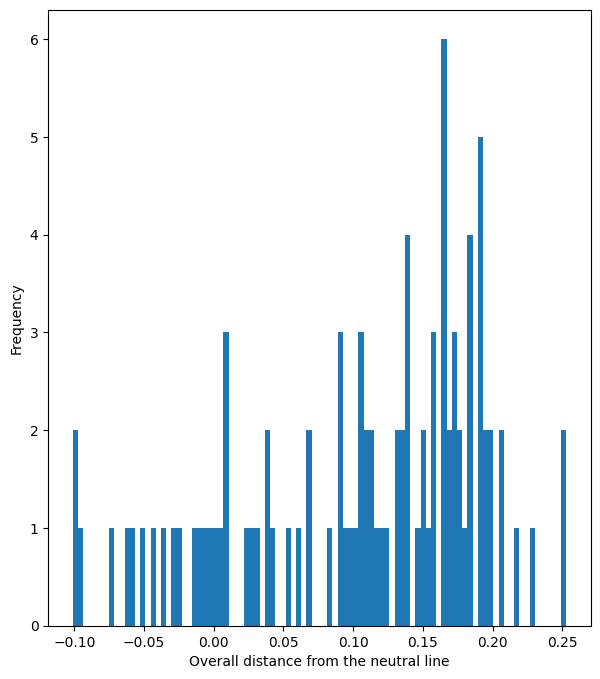

Now we calculate the distance to the neutral line to rank different designs

[26]:

from mvm import nearest

# Calculate distance metric

p1 = np.array([X.min(),Y.min()])

p2 = np.array([X.max(),Y.max()])

p1 = p1 - 0.1*abs(p2 - p1)

p2 = p2 + 0.1*abs(p2 - p1)

distances = np.empty(0)

for i,(x,y) in enumerate(zip(X,Y)):

dist = 0

for node in range(len(x)):

s = np.array([x[node],y[node]])

pn,d = nearest(p1,p2,s)

dist += d

distances = np.append(distances,dist)

# create empty figure

fig, ax = plt.subplots(figsize=(7, 8))

ax.set_xlabel('Overall distance from the neutral line')

ax.set_ylabel('Frequency')

ax.hist(distances,bins=len(distances))

plt.show()

best_i = np.argmax(distances)

best_design = D[best_i,:]

print('---------------------------------')

result = 'The best design:\n'

for value,d_object in zip(best_design,sto_man.design_params):

result += d_object.symbol + ' = ' + '%.3f'%value + '\n'

result += '---------------------------------'

print(result)

---------------------------------

The best design:

w = 85.258

h = 15.242

theta = 3.865

---------------------------------

Let us visualize the distance calculation for three different designs

[27]:

# display distances only for three designs

X_plot = X[0:3,:]

Y_plot = Y[0:3,:]

# create empty figure

colors = ['#FF0000','#27BE1E','#0000FF']

fig, ax = plt.subplots(figsize=(7, 8))

ax.set_xlabel('Impact on performance')

ax.set_ylabel('Change absoption capability')

ax.set_xlim(p1[0],p2[0])

ax.set_ylim(p1[1],p2[1])

p = ax.plot([0, 1], [0, 1], transform=ax.transAxes, color='k',linestyle=(5,(10,5)))

distances = np.empty(0)

for i,(x,y) in enumerate(zip(X_plot,Y_plot)):

ax.scatter(x,y,c=colors[i])

dist = 0

for node in range(len(x)):

s = np.array([x[node],y[node]])

pn,d = nearest(p1,p2,s)

dist += d

x_d = [s[0],pn[0]]

y_d = [s[1],pn[1]]

ax.plot(x_d,y_d,marker='.',linestyle='--',color=colors[i])

distances = np.append(distances,dist)

plt.show()